A classic economic comparison between upfront purchase cost and ongoing operational savings

Energy efficiency is not just an issue for businesses; most individuals or households have also considered questions like:

Energy efficiency is not just an issue for businesses; most individuals or households have also considered questions like:

- Should I leave my old-fashioned light bulbs in operation or replace them with energy-saving devices such as LED lights; and, if so, when?

- When an old light bulb fails, do I buy an expensive energy-saving light bulb or replace it with another conventional light bulb? (I have some spare bulbs, so they cost me nothing more for now.)

- Should I replace my conventional light bulbs proactively even before they fail?

The near-universal context makes this an accessible and straightforward application for the STEM visual software for the reliable modelling of business, with the additional twist that the operational lifetime of a light-bulb tends to be estimated in hours, compared to years or even decades for always-on networking assets.

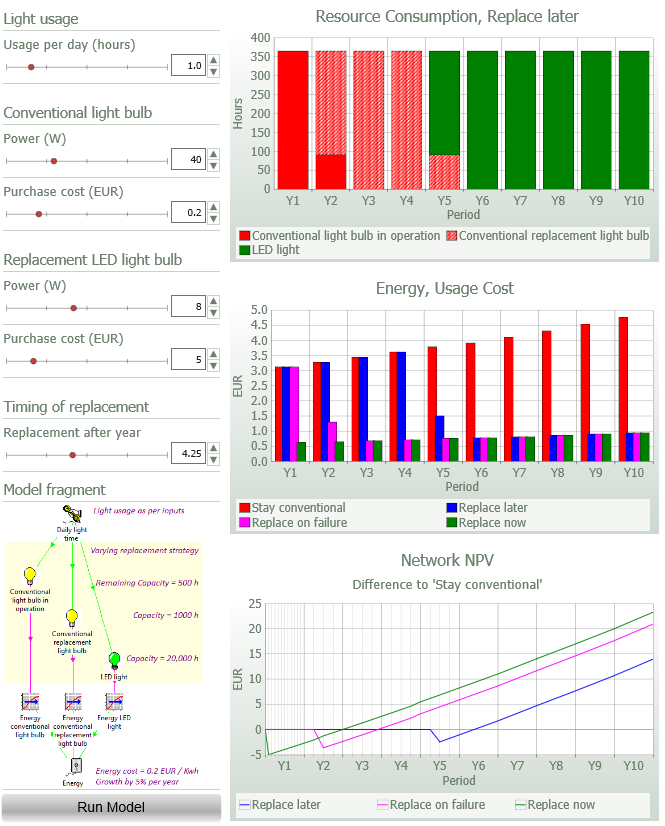

Figure 1: Simplified model interface live on our website

1. Considerations for an economic model

In order to quantify the impact of these decisions and provide answers to the underlying questions, it is necessary to calculate and compare the costs which would arise in a number of different scenarios. First of all, what is different between conventional light bulbs and energy-saving LED bulbs?

| Technical characteristics |

Economic characteristics |

- LED light bulbs use much less power to produce the same brightness – typically 5–8 times less than conventional light bulbs

- LED light bulbs have an operational lifetime of around 20,000 hours, compared to a few thousand hours for a conventional light bulb

- both types of bulb can last for many years but actually operate for only a limited number of hours; thus the focus is on the operational time

- the operational lifetime is also affected by the number of switch on cycles, but we have not considered this explicitly here

|

|

- the purchase cost of an LED bulb is still relatively high, but there is a significant price decrease with time

- a household may have a store of conventional light bulbs and might consider replacement with such a conventional light bulb as a sunk cost

- the cost of energy is increasing

- economic comparisons should be made on the basis of net present value, allowing for the change in value of money over time (but with a low discount factor of c. 2% for a private household, considering the low interest and inflation rates in developed countries)

|

Figure 2: Technical and economic considerations

The central factor for this analysis is bound to be how intensively the light is used. High average usage times lead to higher energy savings and therefore to an earlier return of investment, whereas an infrequently used bulb may never cost enough to operate to cover the cost of a more expensive replacement.

2. Modelling approach

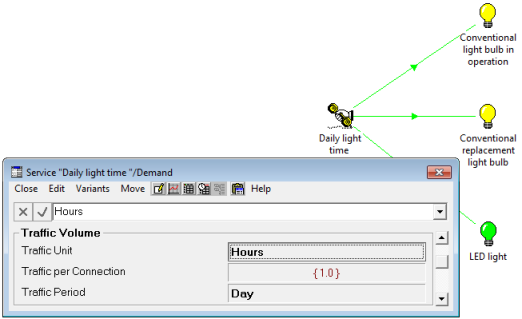

The usage or demand part is represented as a service in STEM. The traffic volume is measured in hours and represents the daily usage time of the current light bulb.

Figure 3: Representation of usage time of light by the Traffic Volume inputs of a service

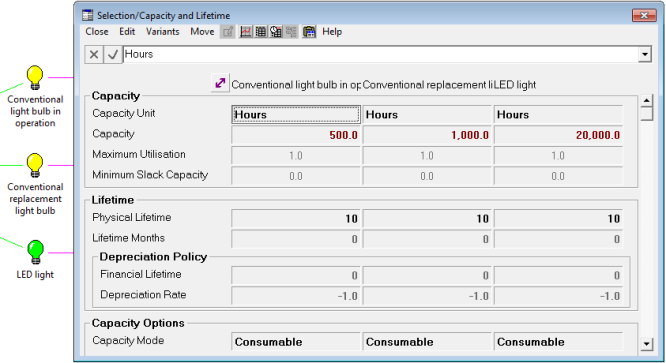

The model compares scenarios in which the household uses either LED or conventional light bulbs. We need to account for the fact that the conventional light bulb, which is active at the beginning, has been already used for a certain time. Thus its capacity in terms of operational lifetime is lower than that of a new conventional light bulb. Therefore, we distinguish between three different types:

- conventional light bulb in operation (with a possibly shorter remaining lifetime)

- conventional replacement light bulb (with standard lifetime)

- LED light.

The different light-bulb types are represented as resources in STEM. The actual physical lifetime is assumed to be ten years and doesn’t affect the comparison; whereas the more significant parameter is the operational capacity of the light bulb, specified in hours. The Capacity Mode input for the resource is set as Consumable – meaning that its capacity is used up over time (as opposed to the more familiar Persistent, which would be used for something like an always-on circuit). STEM automatically accounts for the purchase of a suitable replacement bulb once the capacity has been used up completely.

Figure 4: Capacity parameters of the resources

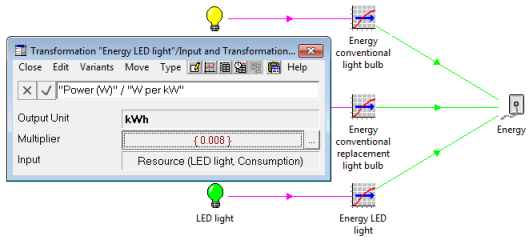

The LED light bulb also uses less power. A multiplier transformation element is used to calculate the energy consumption for each type of bulb (kWh) as the product of the time in operation (hours) and the associated power rating (W), divided by 1000.

Figure 5: Energy cost calculation

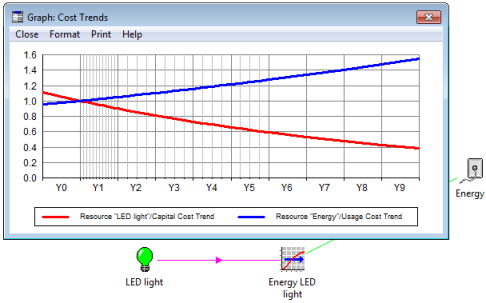

The model must be calibrated with assumptions about the initial costs and associated cost trends for light-bulb purchase and energy, respectively. For a 40W equivalent bulb, we assume an initial price around EUR5.00, decreasing by 10% per annum. The cost of a kWh is assumed to be EUR0.20, increasing by 5% per annum. A discount factor of 2% has been applied for the NPV calculations. All of these are standard inputs in a STEM model which can be readily changed, either on the desktop or in an online presentation.

Figure 6: Separate cost trends for LED light-bulb purchase, and energy

3. Scenarios for alternative decisions and contexts

In order to make a direct comparison of the various outcomes considered, the model is built around a number of variant elements (as follows) which capture the contrasting assumptions and enable the corresponding results to be graphed side-by-side:

- Stay conventional: when the existing light bulb fails (because its remaining capacity has been used up) it is replaced by a new conventional light bulb (for which the Capital Cost input may be set to zero to reflect the perception of it as a free replacement, depending on pre-existence of spares)

-

Replace on failure: when the existing light bulb breaks it is replaced by an energy-saving LED light

-

Replace now: the conventional light bulb is replaced immediately

-

Replace later: the conventional light bulb is replaced at a given point in time (which is specified as a model input).

In the Replace later scenario, a date is specified at which the lamp will be re-equipped with an energy-saving LED purchased at that time (potentially much cheaper in the future). The conventional light bulb might still have remaining operational capacity. It might already have been replaced by one or subsequently more new conventional light bulbs. This scenario reflects a deliberately delayed update of the technology, as opposed to the proactive, early replacement of the Replace now scenario.

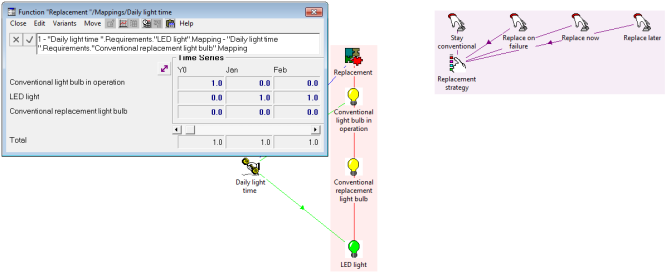

These scenarios control how the demand of the Daily light time service is supported by the three alternative resources over time. The function element in STEM effects a natural replacement between related resources when the capacity of the currently employed resource expires. The scenarios simply control what the currently preferred technology is at a given point of time, and allow for the existing bulb to be forcibly replaced in the Replace now and Replace later scenarios.

Figure 7: Demand mapping swaps support in Y1 in the Replace now scenario

4. Key results

The model is simple and uses just a few elements, but it still gives a good insight into the usage and the economics of the replacement process of a light bulb. Results are generated for a ten-year period, including the first five years in quarters and the very first year in months, showing a more detailed analysis of a replacement in the first year.

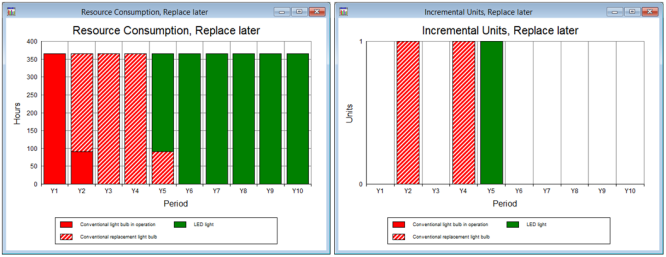

Usage of the different light-bulb types and the replacement/purchase of new light bulbs are shown clearly in the following figure for the scenario Replace later. On the current inputs the conventional light bulb would break and be replaced by another conventional light bulb in the first quarter of Y2. This second conventional light bulb would be used until the end of its operational lifetime in Y4, whereupon it would be replaced again with a conventional light bulb. This is followed immediately by a replacement with LED in Q2 Y5, as this was our specific replacement date.

Figure 8: Light bulb usage and replacement

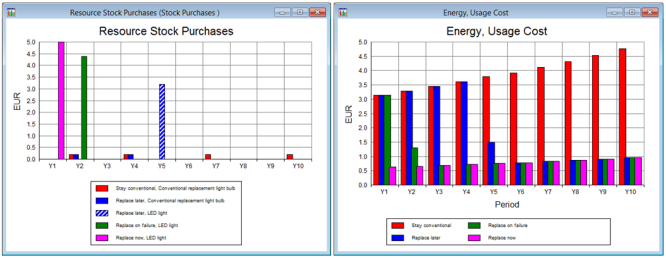

Purchase cost and energy cost are shown in the following figure for different scenarios. The Stay conventional scenario (red) has of course quite low purchase cost but is affected by the increasing cost of energy. Replacement scenarios show the high purchase cost of an LED light, but have significant energy savings.

Figure 9: Purchase and energy cost

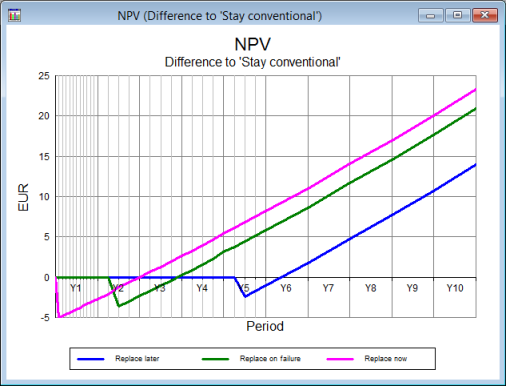

Finally, we compare the NPV of the three replacement scenarios relative to Stay conventional as a baseline. On the current assumptions, an earlier replacement is better, even if the purchase cost for the LED light is decreasing over time.

Figure 10: Scenario comparison relative to Stay conventional

5. It all depends on the numbers, which is why a model helps

As stated at the beginning, the case for replacing the conventional bulb depends as much on its own usage as on the relative costs of the LED light and energy, and the evolution of the associated cost trends. It obviously makes more sense to replace a bulb which operates for several hours each day compared to one which is turned on for only a few minutes.

This article illustrates how an ordinary, everyday question can be answered with a simple model. Implied Logic can work with you to develop a clear methodology for the most complex business problems and has the technology to push such models to the web with just a few clicks.